17-4 Ph Round Bars

- Home

- 17-4 Ph Round Bars

Alloy 17-4 ph round bar or as referred to by its trade names UNS S17400 and Type 630, is kind of precipitation hardened martensitic stainless steel grade. The major alloyants of 17-4 ph stainless steel round bar include chromium, nickel and copper with a significant addition of niobium. 17-4 ph h1150 round bar is an alloy grade that combines high tensile strength and hardness properties with good resistance to corrosion. The 17-4 ph stainless steel round rod is an alloy that is furnished in Condition A or what many suppliers note as a solution annealed condition. Although the Stainless Steel 13-8 Mo Flat Bar offer many advantageous properties, suppliers and manufacturers do not recommend using these bars temperatures exceeding 572°F or for cryogenic applications.

Optimal mechanical ss17-4ph material properties could be achieved by subjecting the bars to an age hardening heat treatments. Heat treating the 17-4 ph h900 round bar to a temperature at a range of 900°F is what imparts the metal with increased strength. Although the corrosion resistance properties of AMS 5643 Steel 17-4 PH Bright Bar rivals that of grade 304 stainless steel in most conditions and its corrosion resistance is generally considered to be superior to the 400 series stainless steel.

Hence, the SS 17-4 PH Cold Finished Bars could be used in those applications which require a combination of moderate corrosion resistance and magnetic properties along with the unusually high tensile strength properties. Alloy grade 630 stainless steel bar can be easily welded as well as processed by conventionally used shop fabrication practices.

17-4 Ph Round Bars Specifications

| Specification | Details |

|---|---|

| AISI | 17-4 PH |

| UNS | S17400 |

| AMS | 5604 |

| ASTM | A693 |

17-4 Ph Round Bars Equivalent Grades

| Standard | Grade | Equivalent Grades |

|---|---|---|

| ASTM | 17-4 PH | XM-19, UNS S17400 |

| DIN | 1.4542 | 17-4 PH |

| BS | EN 1.4542 | 17-4 PH |

| AFNOR | S15700 | 17-4 PH |

| JIS | SUS630 | 17-4 PH |

17-4 Ph Round Bars Chemical Composition (%)

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.07 max |

| Manganese (Mn) | 1.00 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

| Silicon (Si) | 1.00 max |

| Nickel (Ni) | 3.00 - 5.00 |

| Copper (Cu) | 3.00 - 5.00 |

| Chromium (Cr) | 15.00 - 17.50 |

| Molybdenum (Mo) | 0.30 - 1.00 |

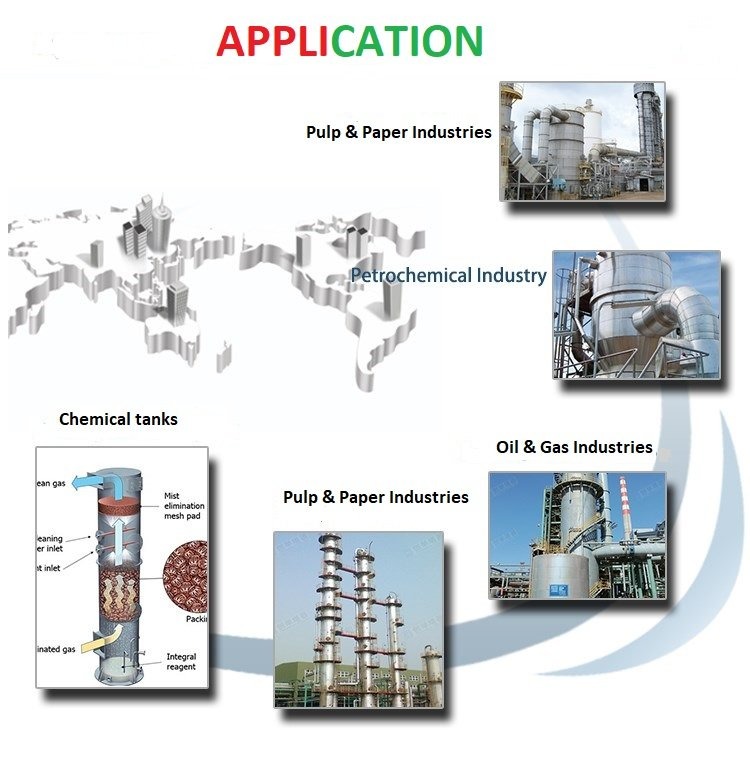

Industry We Serve

- Power Plant Industries

- Aerospace Industries

- Refineries Industries

- Construction Industries

- Oil & Gas Industries

- Sugar Industries

- Petrochemical Industries

- Chemical Industries